Cracking in Elevated Slab

JUNE 2023

santa clara, CA

Overview

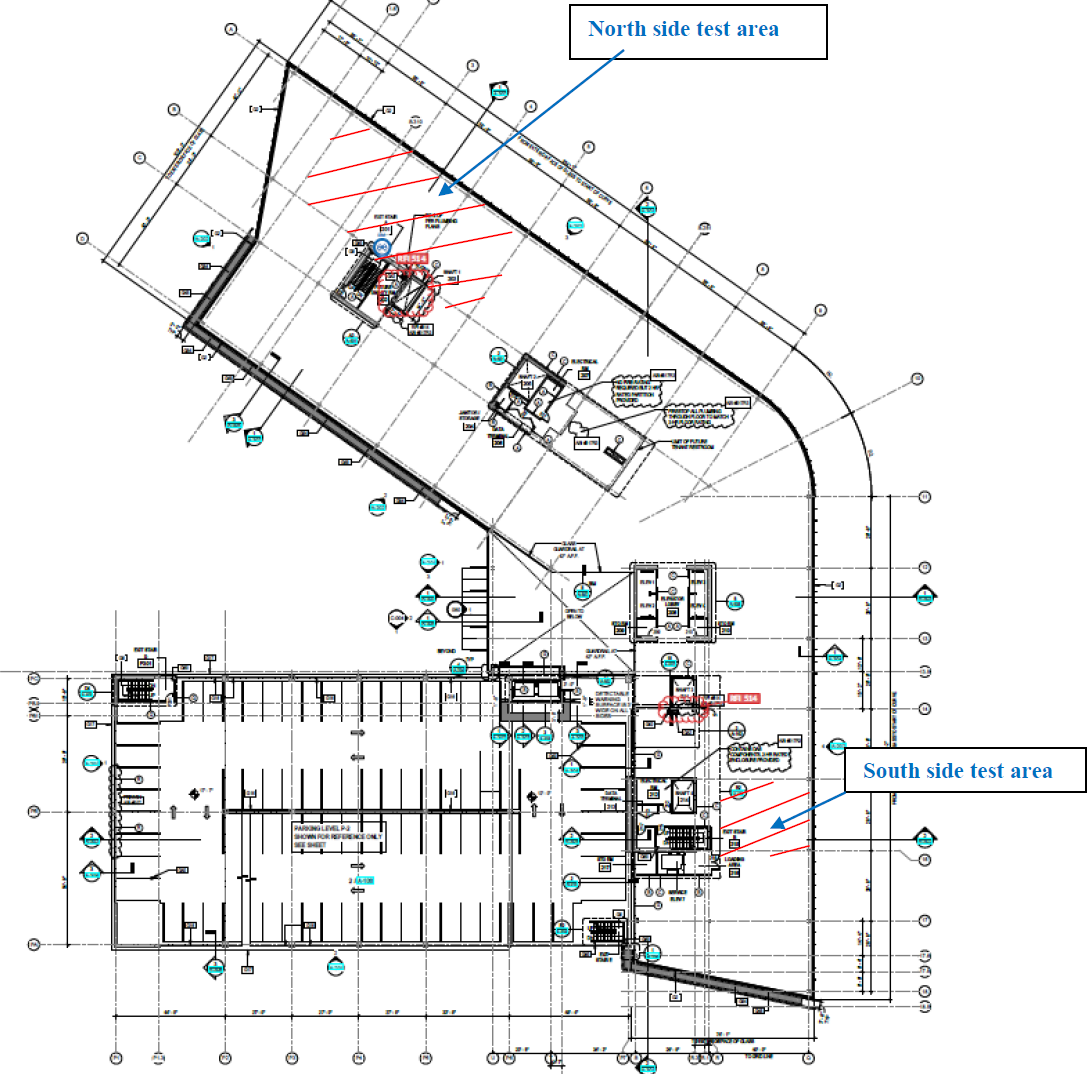

Concrete Science, Inc. was retained to investigate extensive cracking in the 2nd-level elevated concrete slab at a multi-level structure under construction in Santa Clara, CA. Of the twelve levels poured using similar construction methods, the north side of the 2nd-floor slab exhibited the most pronounced and widespread cracking, with patterns including full-depth and plastic shrinkage cracking. The observed damage raised concerns among ownership regarding the slab's long-term appearance and serviceability, even though the structural engineer of record confirmed the slab's structural integrity. The investigation aimed to identify the root cause of the cracking and assess whether the material and structural conditions warranted repairs or replacement.

SCOPE OF WORK

-

Construction drawings and concrete specifications: Examined to understand original design intent, reinforcement layout, and material requirements.

Concrete mix designs and batch tickets: Reviewed to assess the cementitious content, admixtures used, and consistency between batches.

Special inspection reports: Analyzed for quality control measures during placement and curing.

-

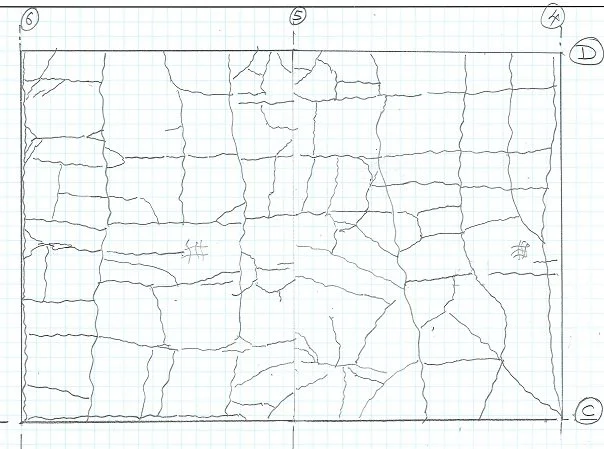

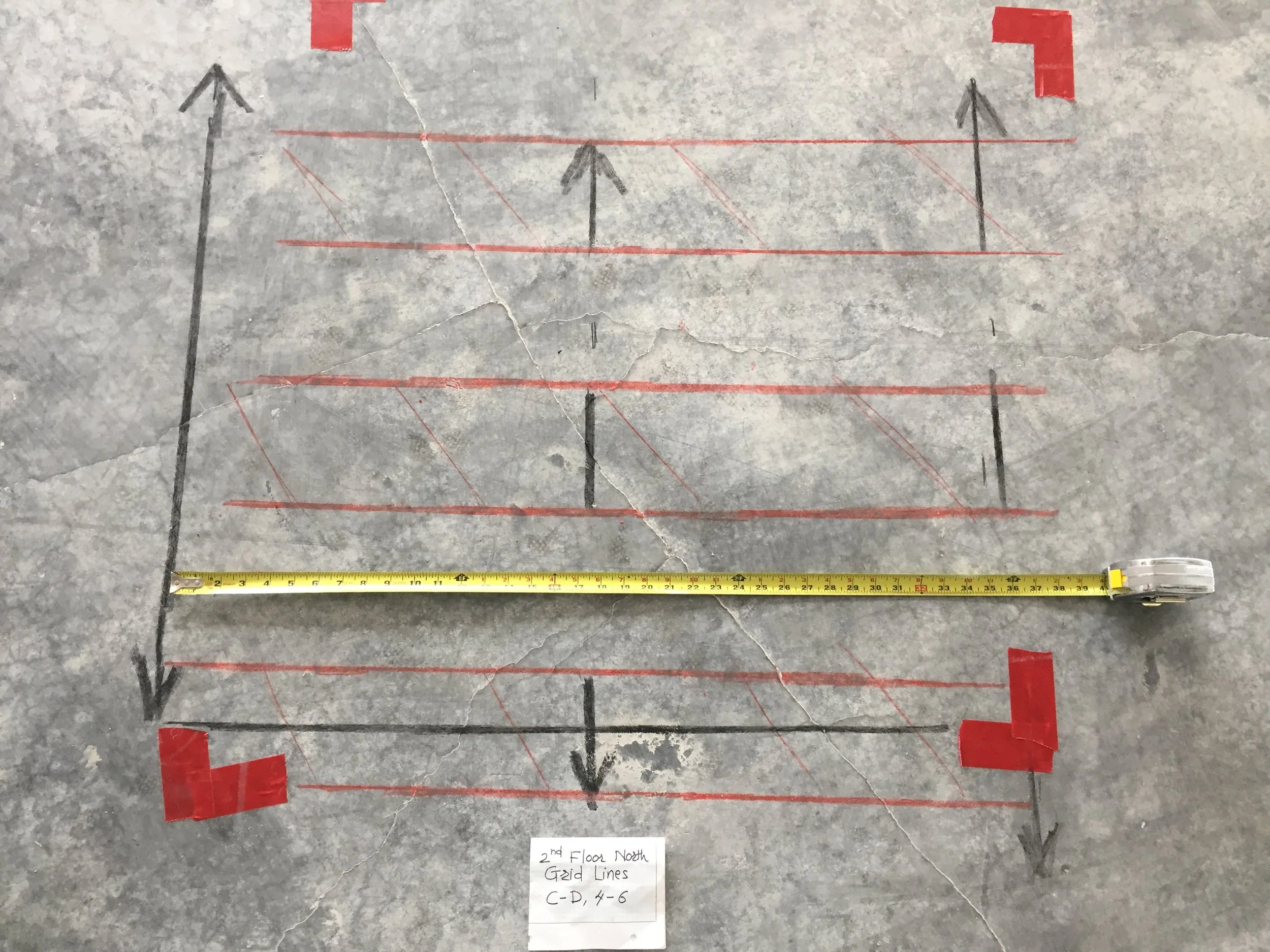

Visual inspection and crack mapping: Performed to identify extent, pattern, and severity of cracking.

Delamination survey: Conducted to detect any separation between slab layers or poor bond conditions.

Reinforcement cover measurements: Taken to compare placement depth and its influence on crack propagation.

Core sampling from both cracked and less affected zones: Enabled physical assessment of in-place material condition.

-

Core compressive strength testing: Measured concrete strength in accordance with ASTM standards.

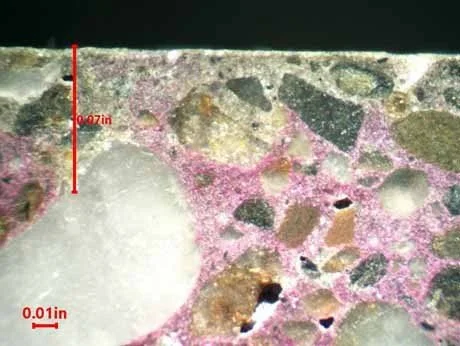

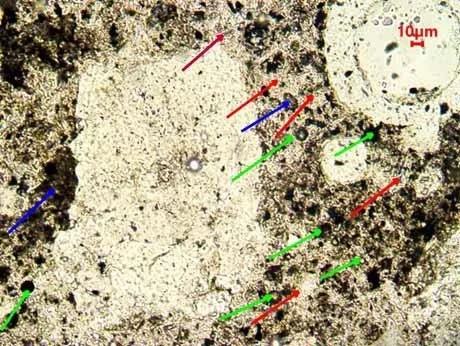

Microscopic petrographic analysis per ASTM C 856: Determined mix composition, hydration, microcracking, and extent of carbonation.

KEY FINDINGS

Field Testing Results from Condition Assessment

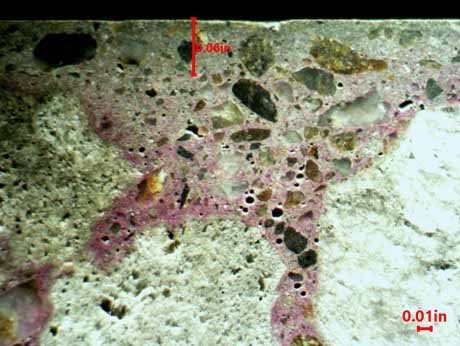

The north side slab exhibited severe multi-directional cracking, including cobweb-like plastic shrinkage cracks.

Crack widths ranged from hairline to 1/8”.

Rebar cover averaged 1.75" north vs. 1.5" south; reinforcement was slightly closer to the surface in the south.

South side had significantly fewer and narrower cracks.

2. Core Compressive Strength Testing

North side: Average 4,670 psi (higher than 3,500 psi design strength).

South side: 5,250 psi.

Despite differences, all cores exceeded strength requirements.

3. Laboratory Testing & Petrographic Analysis Results

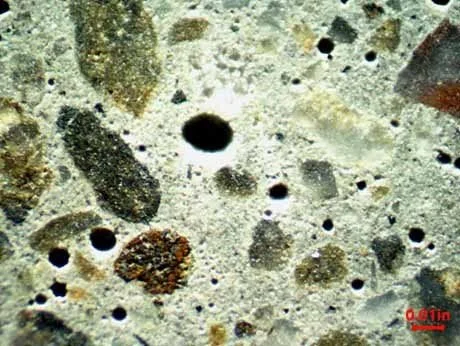

All cores showed well-consolidated, lightweight concrete with perlite aggregates.

Cores from cracked zones showed through-depth vertical cracking, carbonation up to 1.12”, and air content of 4.5% and 4.8%.

The south side core had minor cracking, higher entrained air (6.0%), and included slag instead of fly ash.

All concrete had w/cm ratio of 0.41 ± 0.05 with 6–8% unhydrated Portland cement and 3–5% residual fly ash or slag.

RECOMMENDATIONS & SOLUTIONS

The root cause of cracking was identified as drying shrinkage exacerbated by high cementitious content (715 lb/yd³) and differences in mix design between slab regions.

Plastic shrinkage was also present due to environmental exposure (wind, temperature) during placement and curing.

To improve performance, an epoxy injection of cracks was recommended as a remedial solution.

THE OUTCOME

The findings established that while the slab was structurally sound, modifications to concrete mix design and better environmental controls during curing were crucial to prevent recurrence. Epoxy crack repair was proposed to address the cosmetic and serviceability issues of the existing slab.