Runit Island Dome

december 2013

enewetak atoll, marshall islands

Overview

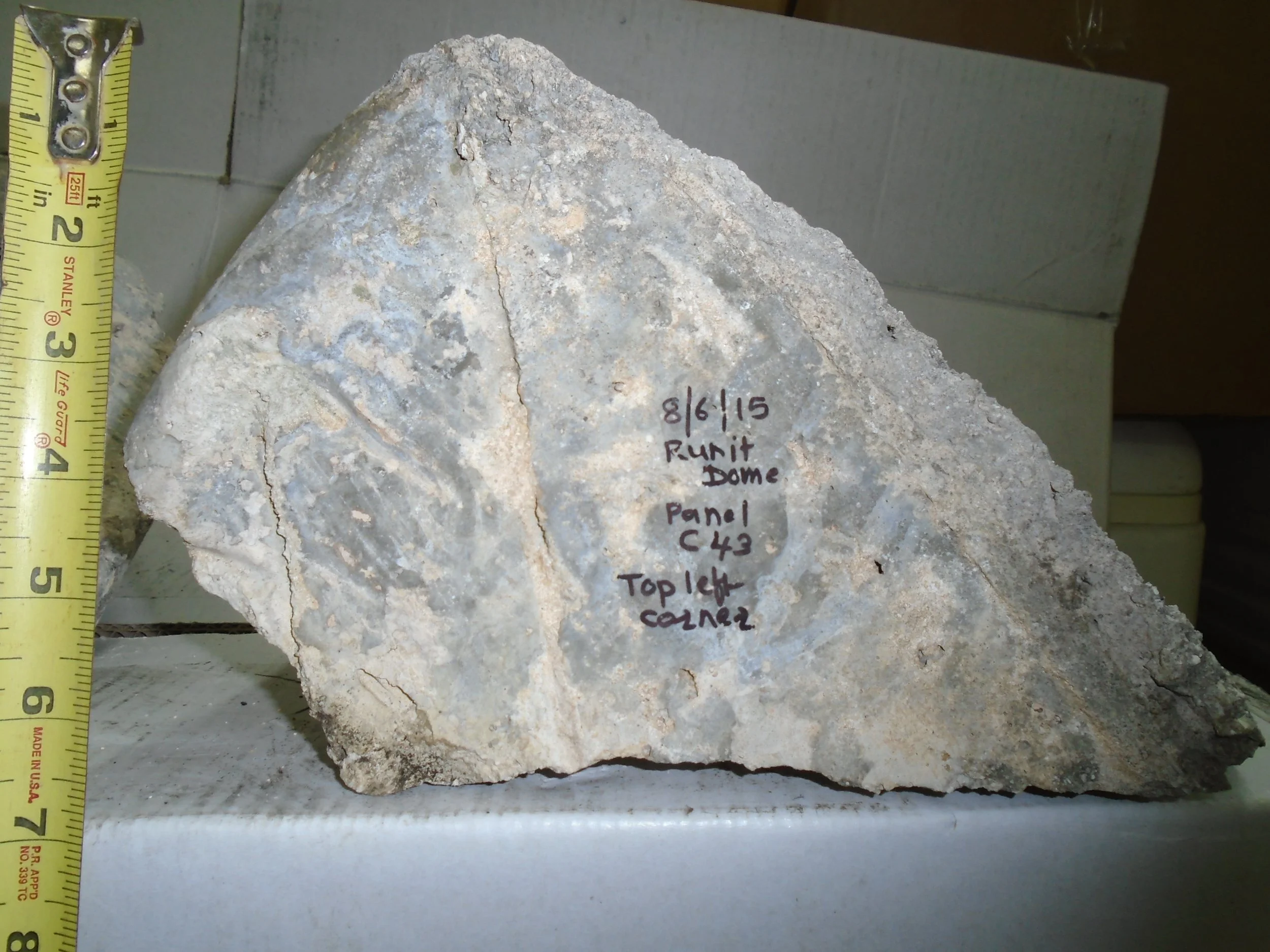

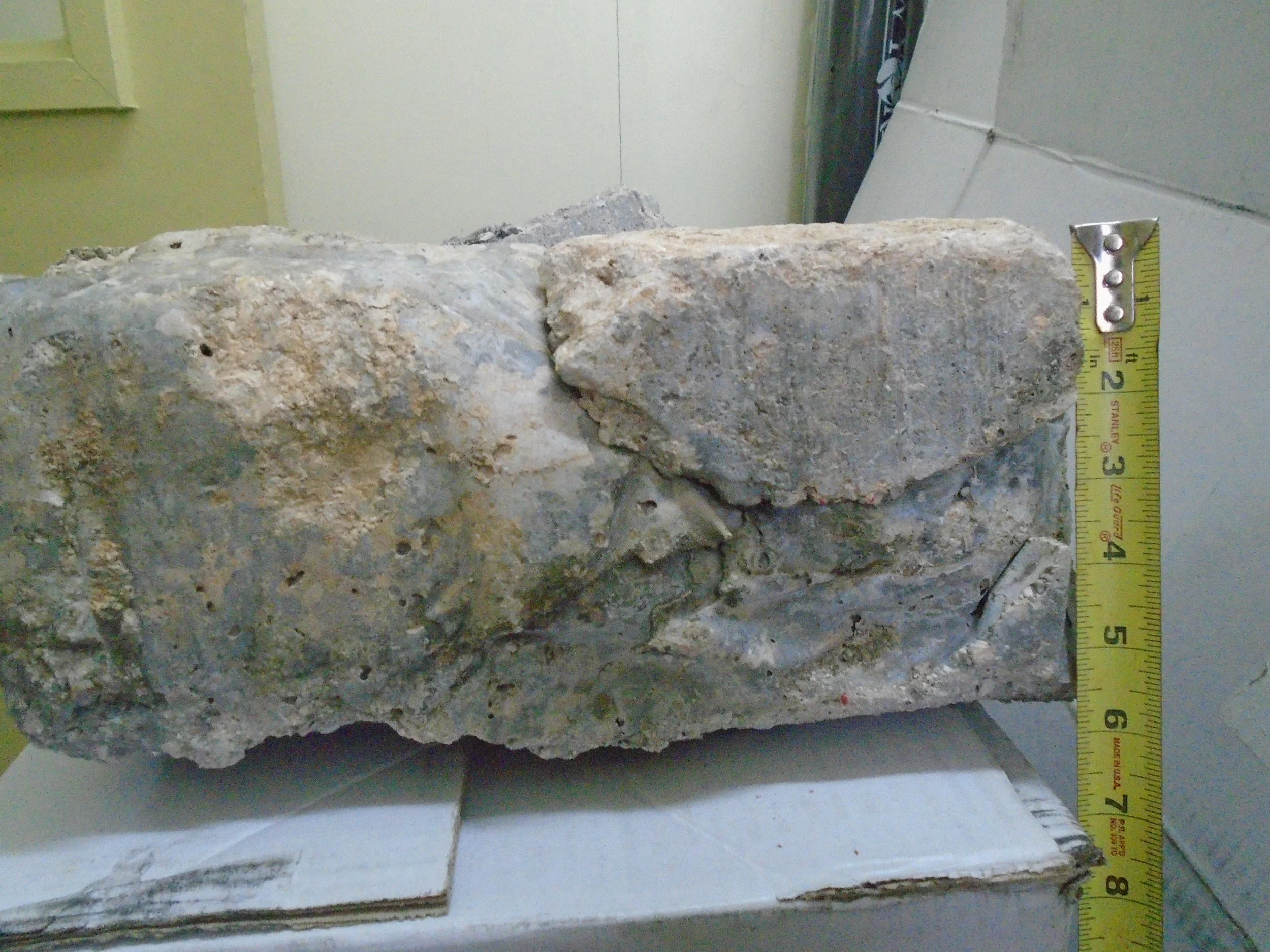

Cracks, discoloration, and spalling had begun to appear across the surface of the Runit Dome, a 60-meter-wide concrete containment structure built in 1979 on Runit Island in the Enewetak Atoll. With concerns about long-term durability and water infiltration, Concrete Science, Inc. was retained to perform a condition assessment and develop a targeted repair strategy.

The Runit Dome is composed of 357 concrete panels placed directly next to each other without expansion joints. Constructed using imported cement, local coral aggregate, and seawater, the dome has endured decades of environmental exposure. This evaluation aimed to determine the extent of structural deterioration and recommend repairs that could be executed efficiently, even in such a remote location.

SCOPE OF WORK

-

Reviewed Ground Penetrating Radar (GPR) and Impulse Echo (IE)/Spectral Analysis of Surface Waves (SASW) data to identify internal voids and structural soundness.

Examined field photographs and existing reports to assess cracking, spalling, and discoloration.

-

Assess concrete panel thickness and joint conditions.

Evaluate visible signs of cracking, spalling, and discoloration.

Identify likely causes of observed deterioration.

KEY FINDINGS

1. Field Testing Results from Condition Assessment

Ground Penetrating Radar (GPR) indicated only a small fraction of the scanned area had probable voids, and less than 1 percent of the area was identified as "questionable."

Impulse Echo (IE) and Spectral Analysis of Surface Waves (SASW) showed that most of the concrete was structurally sound.

Significant crack and spall activity observed, particularly in mid-panel sections.

Evaluated overall thickness of panels (varied from 9.7" to 28.4", average 17.3").

Identified widespread cracking, edge spalling, and water infiltration risks due to unsealed joints.

Attributed damage to drying shrinkage, thermal movement, and chloride-induced discoloration.

2. Observations (From Review of Existing Reports)

Discoloration linked to chloride content from seawater and iron oxides in cement.

Chloride migration due to rainwater infiltration was suspected to contribute to the darkening of the material.

No major voids or extensive delamination was observed.

RECOMMENDATIONS & SOLUTIONS

Crack Repair:

Route and seal cracks using epoxy resin and sealant.

Joint Repair:

Route and seal 15,000 linear feet of joints using elastomeric sealants and backer rods.

Spall Repair:

Remove and patch 52 cubic feet of spalled concrete using high-strength, high-quality cementitious repair material.

Repair Materials:

The repair strategy was designed to allow for local labor training and execution.

Repair Procedure:

Detailed specifications and procedural steps were provided.

THE OUTCOME

Concrete Science, Inc. strongly recommended that a qualified concrete repair engineering firm oversee the repair work. The plan prioritizes water intrusion mitigation and longevity while remaining cost-effective and practical given the remote location. The repair framework was designed to support training and engagement of local labor forces for on-site implementation.