Post-Tension: Chlorides, Carbonation, and Targeted Repairs

AUGust 2024

San Mateo, CA

Overview

Concrete Science, Inc. completed a condition evaluation of a multi-level, post-tensioned concrete parking structure. The objectives were to screen for possible subsurface delamination, check the in-place concrete quality, document the condition of post-tension anchorage pockets, and assess durability risks from chlorides and carbonation.

We combined field screening with laboratory testing to turn findings into next steps. Testing followed industry standards, including ASTM C1218 for water-soluble chloride content and ASTM C856 for petrographic examination. The results guided whether protective repairs and maintenance coatings were suitable options.

SCOPE OF WORK

-

Visual survey to select representative beam and column for detailed sampling.

Chain drag survey across six parking levels to screen for near surface delamination in accessible deck areas.

Nondestructive rebound hammer testing at 100 locations on five beams and five columns to compare relative concrete quality.

Grout pocket observations at post tension anchor locations with concrete cover measurements and photo documentation.

-

Water soluble chloride testing per ASTM C1218 on grout, beam, column, and slab samples taken from 0 to 1 inch depth.

Petrographic analysis per ASTM C856 on beam and column cores from multiple levels.

-

Identification of core and chip locations.

Documentation of visible corrosion at post tension anchorages and correlation with measured concrete cover.

KEY FINDINGS

1. Field Testing Results from Condition Assessment

Delamination screening: Original slabs did not exhibit delamination. Localized delamination was confined to prior repair patches, often near railing bases. Hollow-sounding surface voids were identified and documented.

Rebound hammer: Readings across tested beams and columns were consistent, indicating relatively uniform concrete quality. The estimated compressive strength of the concrete was over 6,000 psi.

Post-tension anchorages: The corrosion condition ranged from none to moderate. The clear cover to strand ends varied from thin to adequate. Locations with greater cover showed minor to no corrosion during observation.

2. Laboratory Testing and Petrographic Analysis Results

Chlorides (ASTM C1218)

Most slab, beam, column, and grout samples had low chloride content. A few slab samples and a grout pocket indicated elevated chloride content at those locations.

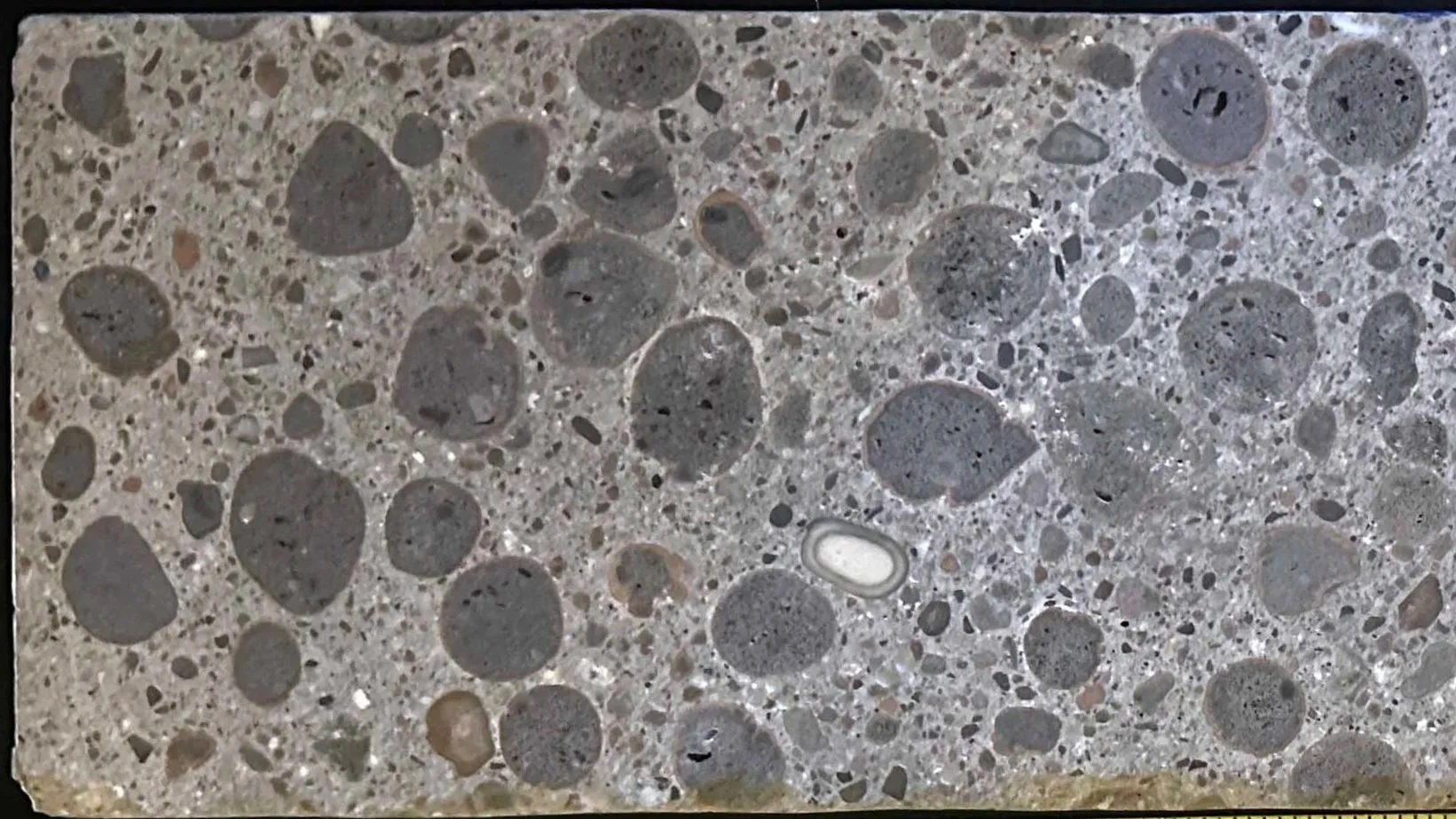

Petrographic Analysis (ASTM C856)

Beams:

Lightweight coarse aggregate with mixed fine aggregate; moderate water to cement ratio; low to moderate total air. Paint layers were bonded. Perpendicular microcracks originating from the exterior surface extended to notable depths locally. Carbonation was generally shallow, with deeper penetration along microcracks in isolated areas.

Columns:

Normal weight aggregate concrete had a moderate water to cement ratio; very low to low total air. Carbonation ranged from negligible to moderate depth. One core exhibited a perpendicular cold joint containing wood fragments and a surface mortar band that was not bonded to an adjoining section; carbonation followed the joint through the core depth.

RECOMMENDATIONS & SOLUTIONS

Repair: Corroded PT Strands:

Structural repair of corroded post-tension strands.

Removal and replacement of delaminated patches with a high-quality repair material compatible with the substrate.

Protect PT anchorages:

Clean exposed strands and hardware, apply an epoxy coating, and restore pockets with high-strength non-shrink grout to limit future corrosion.

Traffic coating at elevated chloride locations:

On slabs, install an epoxy or urethane traffic coating to reduce moisture and chloride ingress.

Protection from Future Carbonation:

Apply a high-quality paint or protective coating system capable of bridging microcracks and limiting carbon dioxide ingress.

Targeted FRP shear strengthening at beams:

At beams with diagonal shear cracking, install externally bonded CFRP U wraps to confine cracking and increase shear capacity, per structural design and product requirements.

THE OUTCOME

We translated the assessment into a practical, step-by-step plan that the owner can use right away. The plan provided clear and actionable items.

By completing targeted repairs, restoring selected post-tension anchorages, strands, and strengthening beams with FRP, the structure has gained many years of serviceable life.

Thank you to our partners

Structural Engineer:

Contractor:

Schwager Davis, Inc.

Design:

Material Supplier:

“The parking garage … was built in 1973 as a post-tensioned structure … the repairs extended the life of the parking structure … including the replacement of multiple failed PT tendons and FRP strengthening of existing concrete beams on all levels”