What is Petrography and How is it Applied to Construction Material?

Mar 11, 2020

By Kate Morel & Ashok Kakade

The definition of petrography is the branch of science concerned with the description of rocks especially by microscopic study. We, at Concrete Science, use petrography as a baseline for examining the concrete or construction material and/or the sand and gravel. Different material that we look at, but not limited to, are:

Concrete

Stucco

Mortar/Grout

Aggregates (coarse and fine particles)

Toppings/overlays/underlayments (paint, gypsum, plaster, epoxy, etc.)

Fire damaged construction material

Asphalt

Interested in Petrography services? Contact us.

Why Petrographic Examinations are Important?

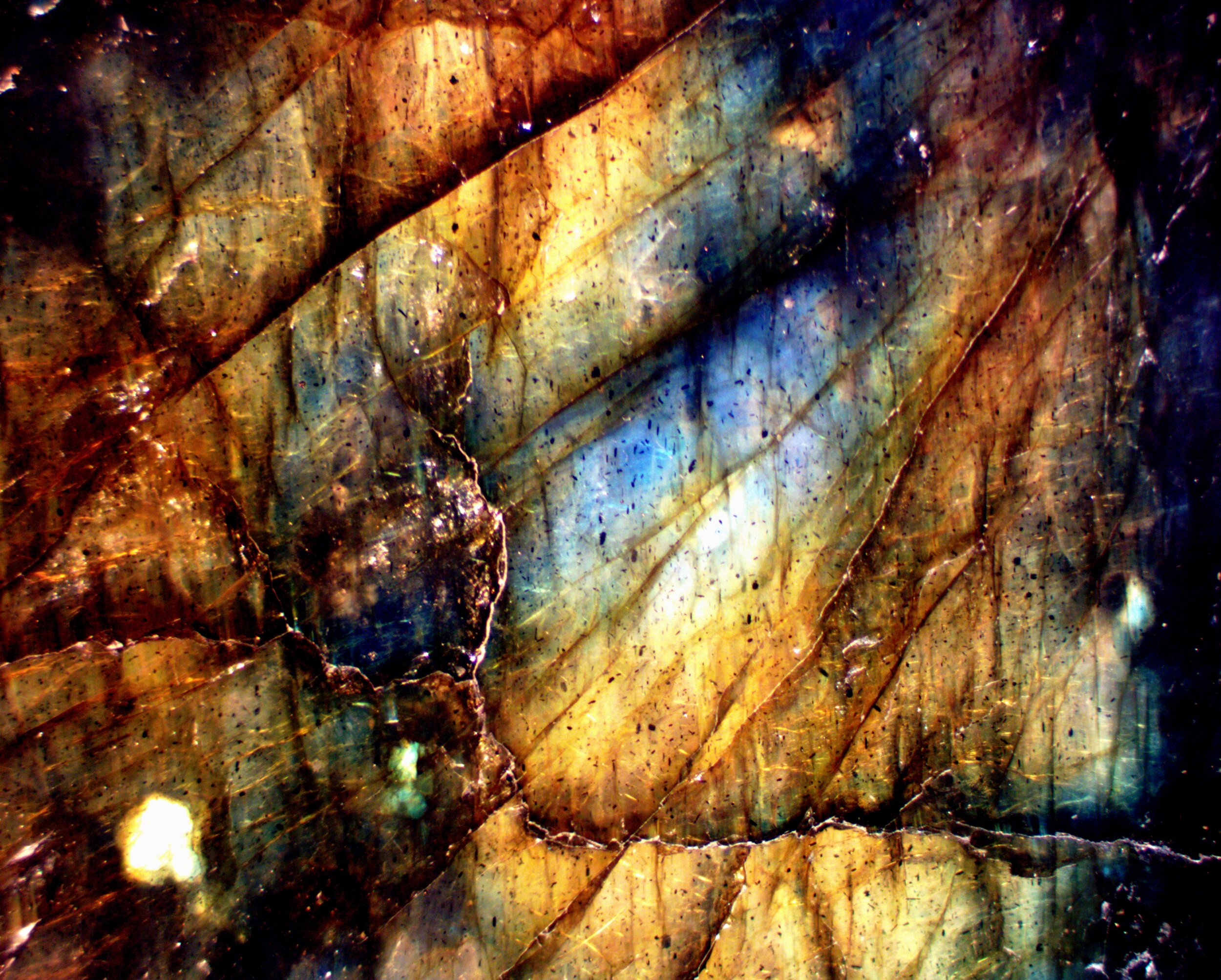

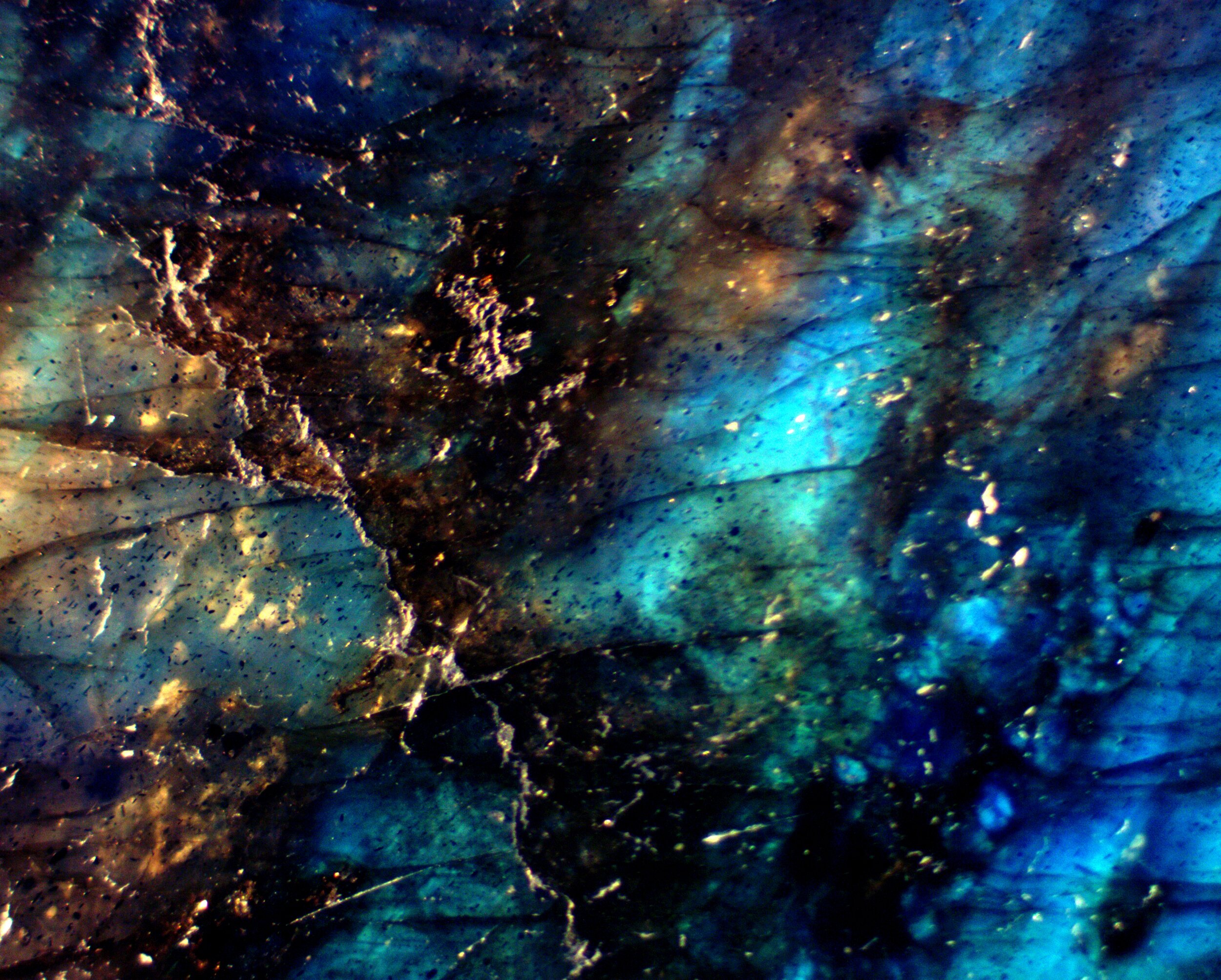

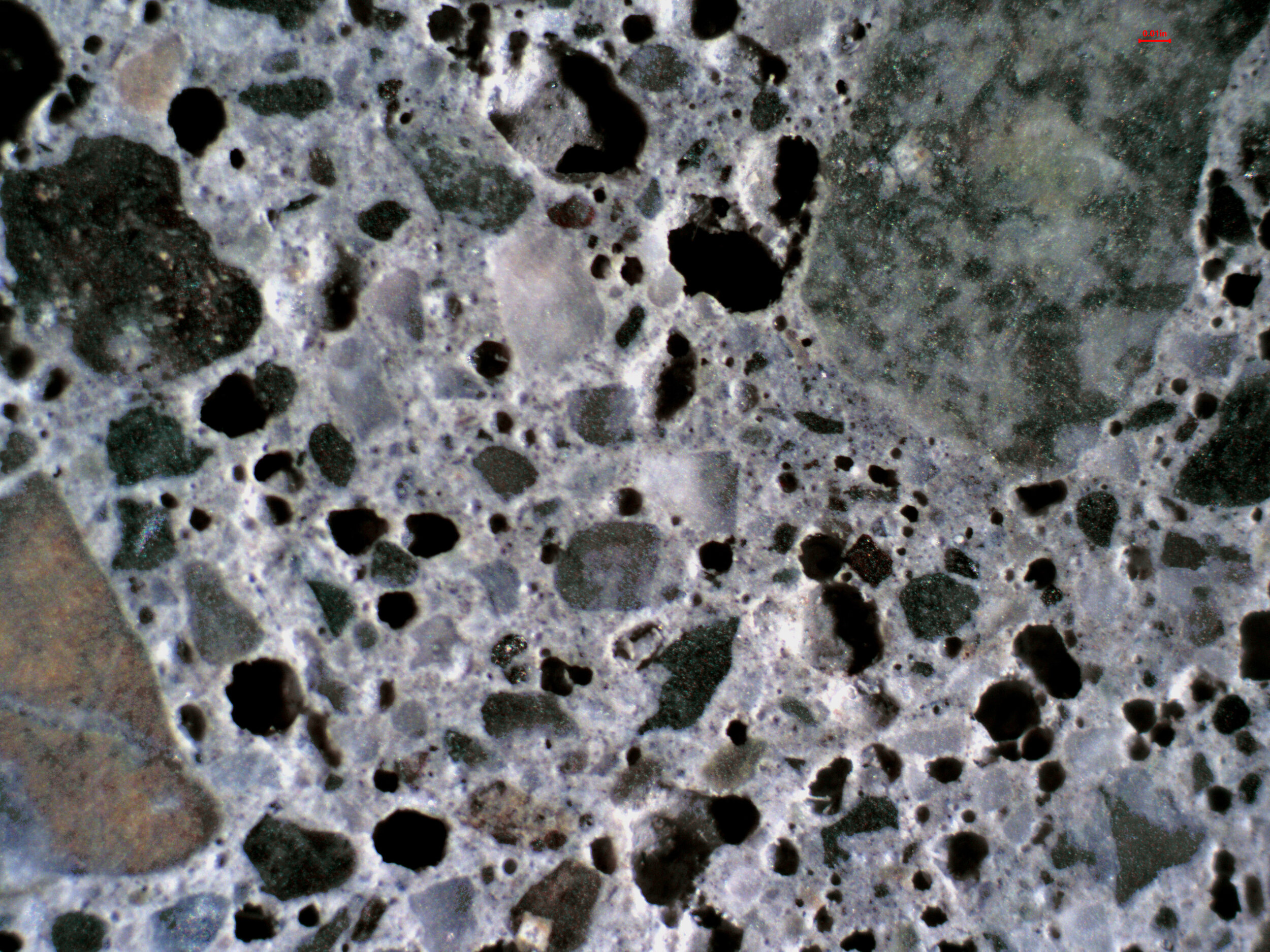

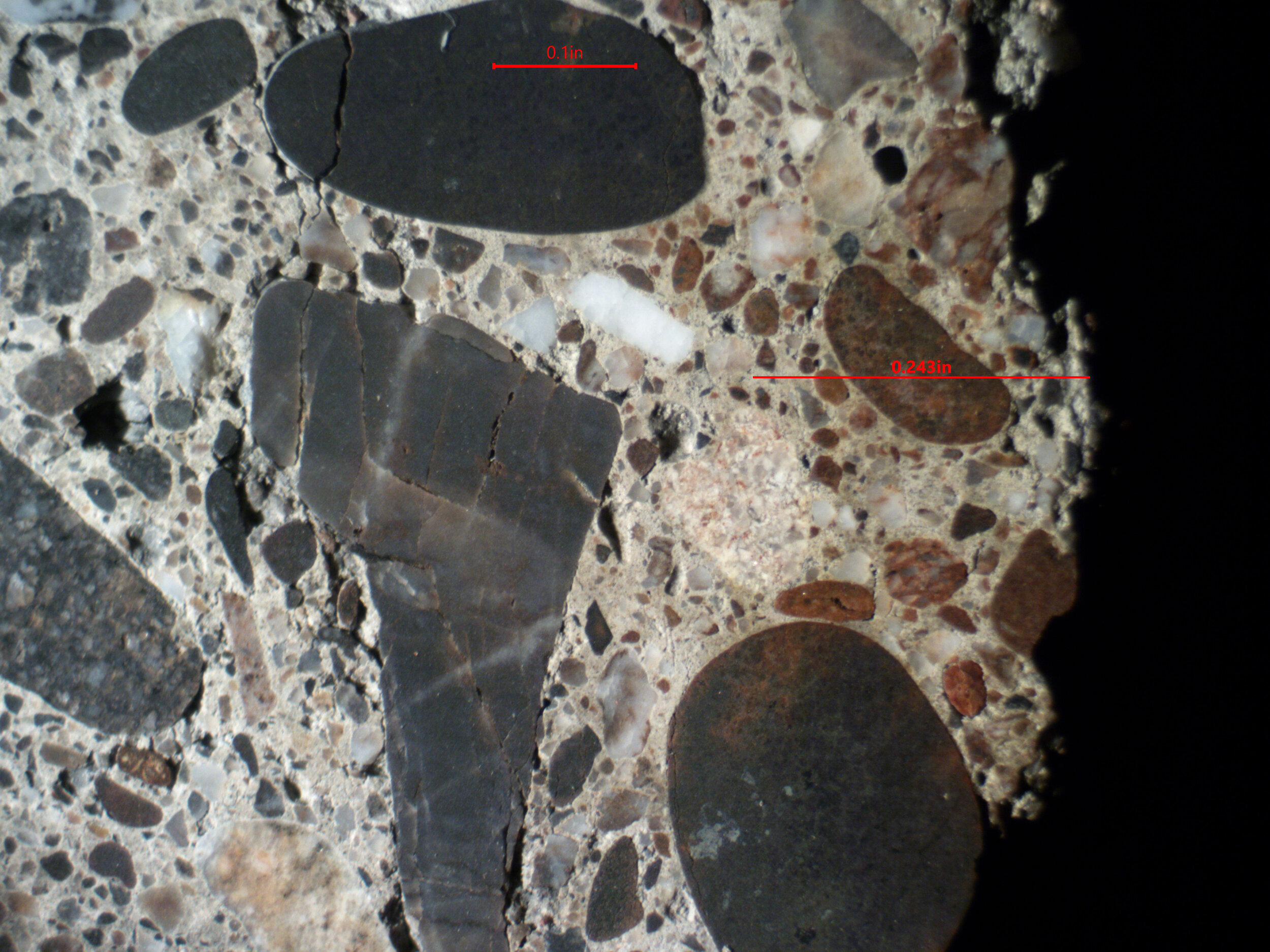

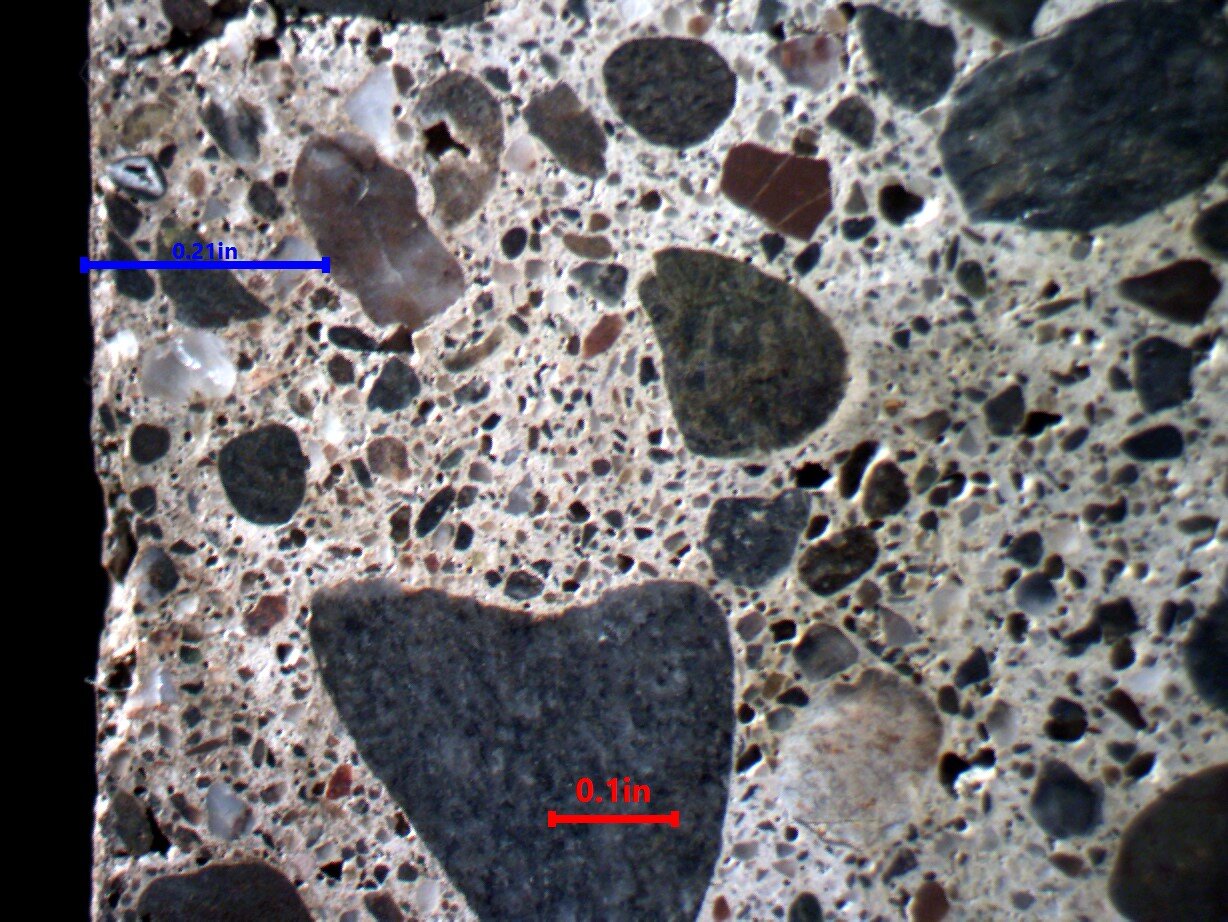

To examine the concrete and construction material, a petrographic examination will be needed. A petrographic examination will determine what is “going on” with the construction material. A petrographer examines the concrete and assesses volumetric proportions and characteristics of the concrete to see how compatible the products are together that create this “man-made rock”. Also, we look at the sand and gravel used in the concrete to make sure it is compatible to the concrete matrix. So, if the concrete or construction material performance is either failing, a problem has occurred, or just comparing the mix design to the sample, a petrographic examination is the best way to assess this. Our Petrographer uses various types of microscopes to evaluate the microstructural quality and the optical properties of the materials. The Petrographic examination consists of a detailed report and identify the failure or deterioration of the material. The petrographer will make recommendations on repairing or replacing the material.

During the examination, the Petrographer identifies:

Concrete quality evaluations: air void analysis, mix design, fly ash, slag, cement, low and high compression strengths, improper finishing, steel reinforcement quality and placement, presence of curing compounds and carbonation.

Concrete deterioration: flooring failures, fire damage, cracking, delamination, scaling, spalling, crazing, pop outs, discoloration, blistering, dusting, efflorescence and curling.

Chemical attacks: alkali silica reaction (ASR), alkali carbonate reaction (ACR), sulfate, chloride, seawater attack and steel corrosion.

Physical attacks: freezing and thawing, wetting and drying, and high temperatures.

Aggregate evaluation: type and composition, quality/compatibility, gradation, flat and elongated particles, and quantify amounts of deleterious/reactive particles.

Mortar/grout evaluation: matching historic mortar, troubleshoot problems, and tuck point compatibility.

Asphalt: crack evaluation and proper repair methods

Common Concrete Problems

Concrete is a very common construction material used in numerous ways. Concrete is used in roads, bridges, buildings, parking structures etc. Concrete is made up by mixing together Portland cement, sand, small stones or gravel, and water with sometimes other admixtures added to it. The admixtures can add durability, strength, and workability to the concrete.

Listed below are the most common problems that can occur to concrete:

Finishing

Aggregate Capability

Air Content

Water Cementitious Material Ratio

Cracking

Finishing

Concrete finishing is a very important aspect. Carbonation can increase when poor finishing techniques are used. If the concrete is finished too early, bleed-water will be trapped and cause the concrete to blister or delaminate. Concretes with a higher water cementitious ratio will have more water rising to the surface that can cause delamination if not allowed to finish bleeding. Blisters form when the trapped bleed-water are in isolated areas causing small dome-like structures on the top surface. The domes can break leaving surface blemishes. Also, if the concrete is finished too late and the surface has already has started to dry, tearing can occur.

Aggregate Compatibility

Aggregates are an integral part of the concrete. There are several types of problems that can occur. Pop-outs are where soft and friable or reactive particles near the top surface expands and pops the top surface off. The reactive particles happen when the aggregate contain very fine grained or amorphous silica react with an alkaline-rich paste causing expansion. These pop-outs can be various sizes depending on the size of the offending particle.

Air Content &

Water Cementitious Material Ratio

Air content is very important where the weather is extreme. Water travels through the concrete through the air void system. If the weather gets below freezing, the water trapped in the concrete will start freezing. If this occurs, the water needs to move throughout the slab. If the air void system is low, the water will have less places to go causing it to crack and deteriorate.

Concrete with a high water cementitious ratio will take longer for the bleed-water to be released from within the concrete. If the concrete is finished too early, bleed-water can be trapped and cause delamination. High water cementitious paste also is weaker. With such a high water content, the cement grains are reduced and the paste porosity is increased causing weakening in the paste. Carbonation rate can increase with a high water cement ratio because of the increase in porosity.

Cracking

Macro and Micro-cracking can occur as drying shrinkage cracks or as plastic shrinkage cracks.

Drying shrinkage cracks are predominantly vertical with the crack lessening with depth. Drying shrinkage macro-cracking can occur when control joints are cut late, poor control joint spacing, or uneven subgrade or restraints. The macro-crack is when a large crack can be seen without a microscope and typically proceed to the bottom of the core. Drying shrinkage micro-crack are fine cracks near the surface of the concrete. The general cause of these micro-cracks are the loss of water by evaporation due to poor curing. Concrete with high water cementitious ratio tend to be more susceptible to change in volume.

Plastic shrinkage cracks occur when the concrete is still in the plastic stage with the significant moisture loss by evaporation. Additional water added at the time of finishing the concretes surface can cause this type of cracking. Reworking the bleedwater into the surface paste increases the water cementitious ratio which increases the chance of plastic shrinkage micro-cracks. The concrete surfaced experiences a rapid loss of moisture due to heat, dry and windy conditions can produce these micro-cracks.

Stucco

Stucco is a construction material consisting of Portland cement or lime, sand and water as the base material. The stucco becomes a hard and brittle substance once it is hardened and can easily crack if not applied or reinforced correctly. Typically stucco is placed in three different applications: scratch coat, brown coat, and the finish coat. Cracks and delamination can occur if moisture gets between the stucco layers or underneath to the wood building structure. Efflorescence can also cause staining, cracking and delamination.

Mortar

Mortar consists of material made of Portland cement or lime, sand and water found between brick or other masonry material. Most reasons for mortar to come in for examination is for building rehabilitation or match old/historic and existing mortar. We also examine to see if there is an incompatibility or deterioration between original mortar and tuck-point. Efflorescence also can become a problem by deterioration of the mortar through cracking.

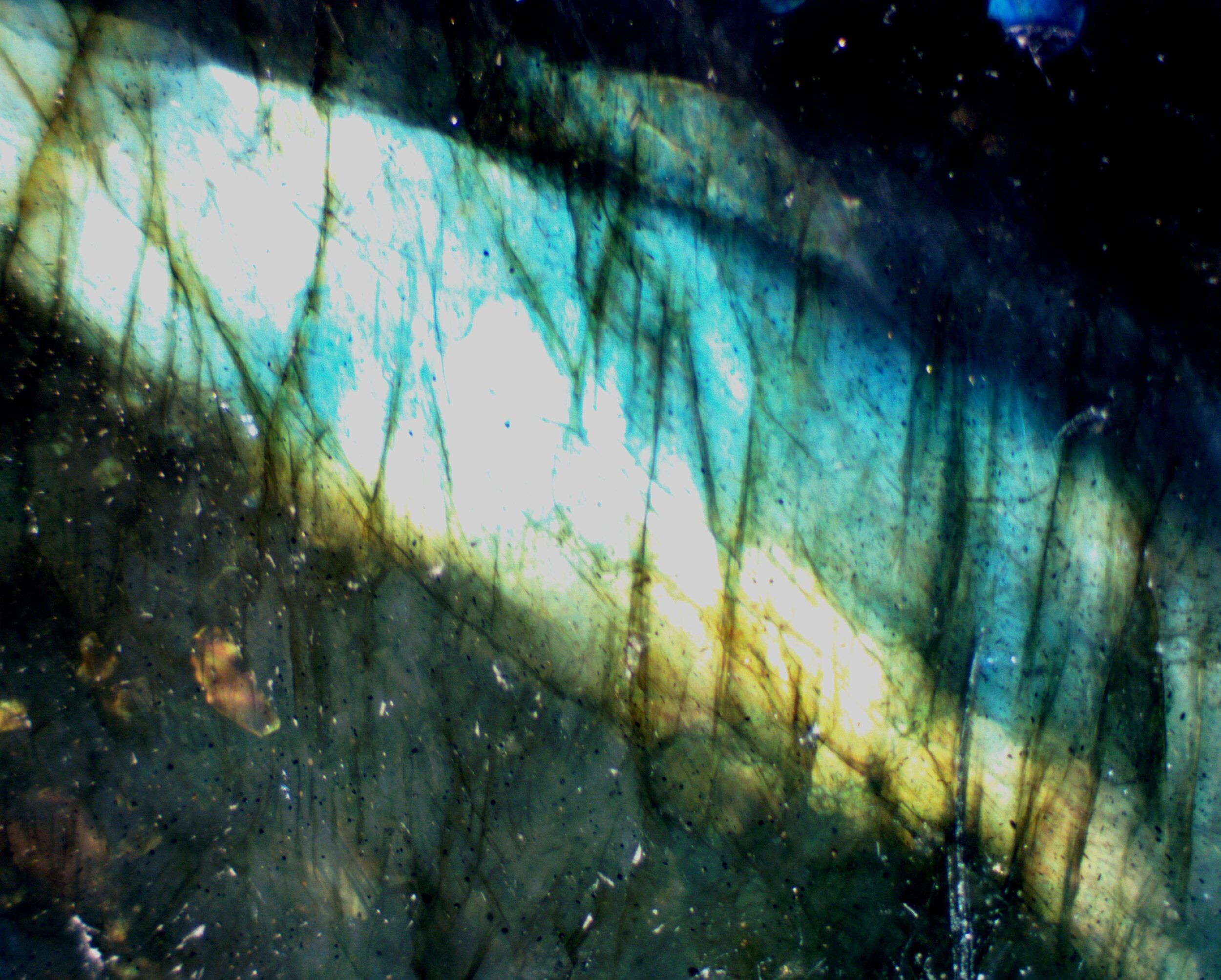

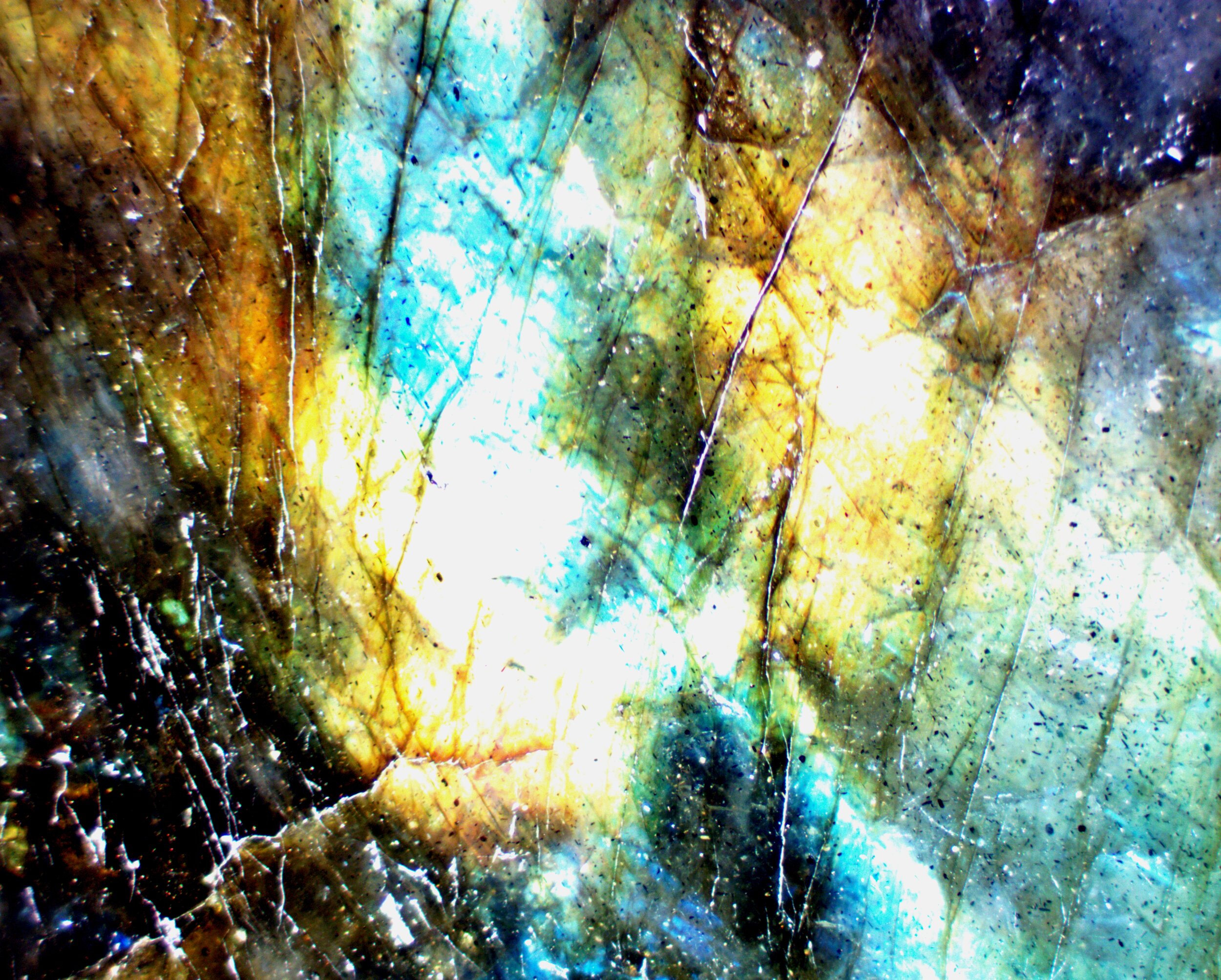

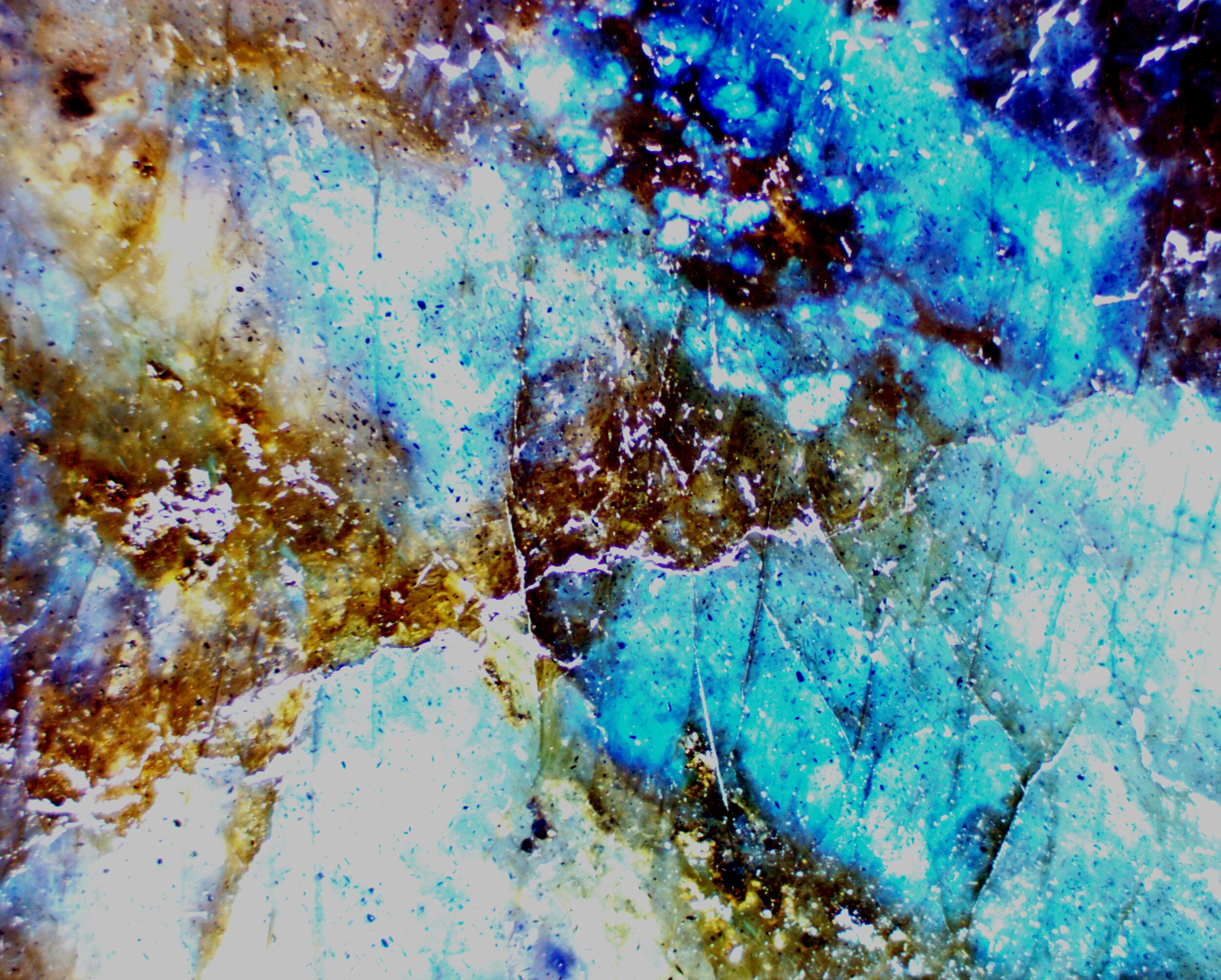

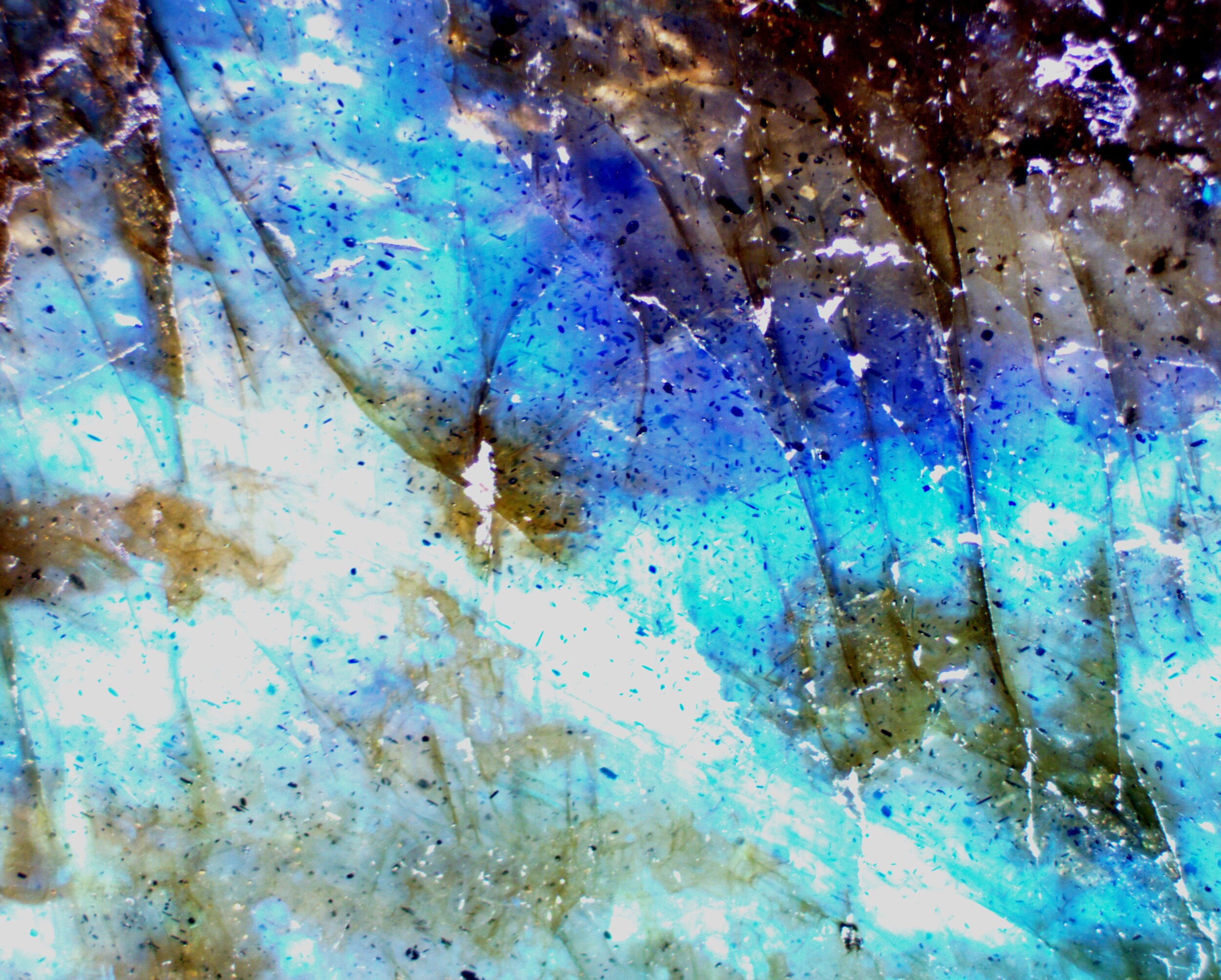

Aggregates

Aggregates come in different forms and sizes. The aggregates used in concrete and construction material are coarse and fine particle categories. There is natural which is alluvial, bedrock, and fluvial aggregate. Another form of aggregates are manmade which is the expanded shale, blast furnace slag, and recycled concrete.

The natural and manmade aggregate can cause potential problems within the concrete. These aggregate particles can react with the cement paste and cause alkali silica gel or alkali carbonate reaction. The reaction can cause the aggregate to expand and crack the paste. Some aggregates are soft and will expand within the concrete and cause the concrete to deteriorate. Metallic or sulfur rich aggregate particles can cause staining or expansion within the concrete. These are a few examples of problems that can occur. With getting the aggregates tested, we can eliminate the chances of having issues due to the aggregates. The tests will inform you what type of particles and the percentage within the given sample.

Other Materials

Topping/overlays/underlayment

This is a very broad area and it refers to anything placed on top of the concrete or construction material. Most of the time it is a cement based or gypsum based product or it could be a material like an epoxy, tile, or a membrane. It can, but not always, have some kind of fine aggregate particles imbedded within. We will look at how well bonded the layer(s) are, if there is an adhesive or bonding agent in between the layer(s), how many layers and what they all consist of. We can assess the compatibility of the layers to each other and to the base concrete.

Fire Damage

Concrete and stucco can hold up well when in a fire and does not penetrate very deep. However, the material can become weakened and cracked. The paste in the concrete has some available water that helps strengthen the concrete and hydrate the cement particles within it. Once a fire occurs, the concrete paste will dehydrate and can change colors when heated to high enough temperatures. The aggregates within the paste can also go through a change in color depending on the available iron content within them. We take a look at the quality of the non-damaged area of the concrete and the aggregates used in the concrete. We then compare it to the fire damaged area and see if the quality of the concrete was compromised. An assessment on the depth of the fire can inform you of the condition of the material and if a repair will be needed.

Asphalt

Asphalt is great for roads, driveways, and parking lots. Over time though it deteriorates causing cracks to form. Usually a slurry will be placed into the cracks to help fill the gaps or a slurry laden mat would be placed between the existing asphalt and the repair that is being placed on it. We can identify if the slurry was used or if the mats are in place and properly installed.

Standards Used for Testing

ASTM standards used for testing the construction material are:

ASTM C 295 - Petrographic Examination of Aggregates in Concrete

ASTM C 457 - Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete

ASTM C 856 - Petrographic Examination of Hardened Concrete

ASTM C 1324 - Examination and Analysis of Hardened Masonry Mortar

We provide services to owners, general contractors, engineers, project managers, material suppliers and more. Call or email us today for a quote!